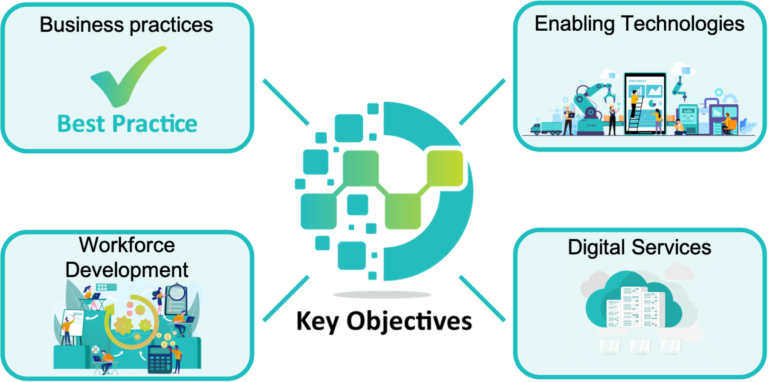

- Enabling Technologies, DENiM will leverage the convergence of innovative digital technologies including Digital Twin, IoT, Cloud/Edge Computing, Machine learning and Modeling and Simulation, to provide advances services towards energy reduction, cost reduction and sustainability improvements;

- Digital Services, tools and mechanisms will be developed to transform digital data extracted from heterogenous sources (shop floor, machines, planning, quality, maintenance) into real-time, actionable, energy- centric insights;

- Workforce Development, new digital skills will be developed to enable industry to take advantage of digital services and technologies, gaining a better knowledge of the actual energy demand of machines/systems/plants as well as automating production processes;

- Business Practices, DENiM will showcase advanced digital technologies for energy management and will adopt energy related standards, contributing to working groups for the enhancement of current standards and the uptake of these across DENiM pilots sectors.

ENABLING TECHNOLOGIES

- Objective 1: Enable sharing of energy and environmental data across sectors

Challenge

Regional governments often set out information mandates relating to energy efficiency (benchmarking, energy ratings and energy audits) that require access to large data sets in a non-standardized and different way between sectors, causing costs of inefficiency.

Solution

DENiM will leverage existing semantic frameworks (e.g., W3C Web of Things framework, Building Energy Data Exchange Specification (BEDES)) and Standards (e.g., ISO / TS 50008: 2018 Building energy data management for energy performance) in order to support the formal specification of the data for integration and exchange with external digital services and to provide guidance for the systematic exchange of data.

- Objective 2: Digitisation framework for secure data and system integration for energy management

Challenge

The challenges associated with reliable data collection (interoperability, heterogeneity, security and privacy) require new methodologies and architectures to support cost-effective instrumentation, processing, storage, management and sharing of such data. A scalable architectural approach is necessary to automate collection by incorporating secure and privacy-preserving data integrity strategies to ensure that high-quality, continuous, traceable data can be provided and leveraged by advanced digital services.

Solution

DENiM will develop a digital platform built on well-established reference architectures consolidated in the Industry4.0 space (RAMI4.0, IIC) by incorporating solutions with a “plug and play” approach in order to integrate the portfolio of protocols used in manufacturing to address interoperability and the heterogeneity of systems.

DIGITAL SERVICES

- Objective 3: Holistic Modelling for Continuous Performance Assessment

Challenge

Understanding energy performance is a complex task and is influenced by many facets within the manufacturing process. Generating models is currently labour intensive and relies heavily on large data sets of high-quality that is not always available. Existing approaches and mechanisms are generally applied to support the creation energy-performance models for a specific asset and are rarely integrated within a larger plant wide view.

Solution

Tools and mechanisms to support the creation and composition of digital models to support accurate energy performance assessment of assets, systems or processes that can be used to assist in the identification of energy saving potentials, fault detection and control optimization supporting energy-efficient initiatives by providing an independent and accurate measurement and verification of a manufacturing process.

- Objective 4: Continuous event-driven Planning and Decision Making

Challenge

Decisions relating to energy are often independent of the production process; therefore, advanced information retrieval and better recommender systems adaptable to advanced interface technologies are required. Current energy-efficient activities occur in silos and impact is not typically considered across the whole facility, so while savings can be made, stakeholders cannot react proactively in an integrated manner.

Solution

DENiM will leverage existing methodologies for optimising energy efficiency such as energy auditing, LCA, LCCA, process optimisation, scheduling, and enhance these through the integration of real-time data and automated assessment tools that can be utilised throughout the value chain. Decision support tools will cover production planning and scheduling, fault detection and diagnosis of assets, integration of renewable energy and visualisation of energy flows that support continuous energy performance auditing.

WORKFORCE DEVELOPMENT

- Objective 5: Digital Maturity, Skills & Training

Challenge

The increase of production processes that change dynamically, the acceleration of digital of transformation and new technological development call for more skilled people and consequently new approaches to education and training are required.

Solution

To maximize the potential for digital transformation, an organisation maturity index and a DENiM Worker Profiler, the digital maturity of a specific organisation and an assessment of the skills gap will be performed, and a training plan designed to eliminate the gap and support continuous learning will be identified.

DENiM will also leverage the Teaching and Learning Factory paradigm along with a community of practise approach that brings education into the factory floor providing learners with hands-on-experience and opportunities for testing and evaluating the potential of new technologies, promoting their acceptance and adoption.

BUSINESS PRACTISES

- Objective 6: Cross-Sector evaluation of Energy Management Technologies

Challenge

While individual, each industry sector has a common goal to reduce energy and improve the sustainability of their products overall. As such, each sector leverages the same or very similar technology to support this but often result in the development of bespoke solutions for managing their energy.

Solution

DENiM will demonstrate and replicate the deployment of the platform across four different industrial sectors, each with their own requirements, constraints and targets. This will showcase advanced digital technologies as a key enabler for energy management and transferability of the solution across different sectors and different companies.

- Objective 7: Promote Best Practices for Sustainable\Energy Efficient Manufacturing

Challenge

While both digital technologies and energy efficiency is high on the list of priorities for many industrial sectors there are still significant barriers hindering them to achieve the potential energy reduction from their manufacturing systems including lack of access to data, maturity of digital technology in their sector, minimal correlation between energy flows and production planning processes, complexity of the processes and lack of digital skills. With industry as a whole adopting similar technologies and systems there is a clear need to establish and exchange best practice across sectors.

Solution

Looking at heterogeneous industry sectors, DENiM will establish and inform best practices for energy- efficient manufacturing system management relating to: digital technologies for reliable data collection and sharing; sustainable driven manufacturing system management; digital twin for sustainable manufacturing processes; digital maturity and collaborative energy management; active participation in the energy transition; digital skills for energy efficient management.

- Objective 8: Standardisation and Certification for Energy Performance Monitoring and Auditing

Challenge

Several standards exist to support continual improvement, for example ISO 50002 – Energy Auditing, ISO 50046 – predicting energy savings, ISO50001 – energy management system, ISO 50006 – Energy performance measurement, DS2403, SS627750, EN16001 and many others. To ensure these standards are utilised it is important to provide guidelines and tools to support decision makers select the correct standard approach that best meets their needs for continuous energy performance optimisation.

Solution

DENiM will adopt the most relevant standards for the different processes of energy performance management and ensure the developed services can support these approaches. Emphasis will be placed on energy related standards, however other open standards relating to digital twin and collaborative digital platforms (e.g., MIMOSA/OpenO&M) will be considered. DENiM will engage with the appropriate working groups and standards bodies to contribute to the enhancement but also uptake of these across the pilot sectors.

- Objective 9: Data Protection, Legal & Ethical Framework

Challenge

Concern is rife across the industrial sector over data protection, security and privacy, particularly with the deployment of IoT and cloud technologies that imply the production of data which can be used for various purposes. The major risk raised by this technology is the loss of control on data by the data provider. Indeed, data is produced by the connected device without the user knowing when and what purpose for that creates risks relating to the loss, mismanagement or exploitation of commercially sensitive data.

Solution

Developing a digital, collaborative platform, DENiM will consider from the outset, the legal, data protection and ethics aspects by incorporating these activities in the project development. DENiM will develop a robust legal and ethical framework that enables the creation of collaborative energy management approaches (internally and externally) as well as the development of new methodologies for leveraging digital transformation for energy management in manufacturing. This also includes approaches for knowledge sharing between sectors.