The industry sector was responsible for 37% of the total global energy use in 2017, representing a 1% annual increase in energy consumption from 2010, with growth of 1.7% in 2017 following much slower growth of 0.1% the previous year . The increase in energy consumption is driven by escalating production in energy-intensive industry subsectors.

The primary characteristic of Industry 4.0 is the digitisation of manufacturing processes, which offers opportunities for energy saving through the optimisation of or replacement of technologies, the application of new software tools for energy efficiency management or adaptation in the business processes. Energy efficiency remains one of the most effective short to medium term targets to reduce industry carbon footprint and needs to be considered at all stages of the manufacturing process.

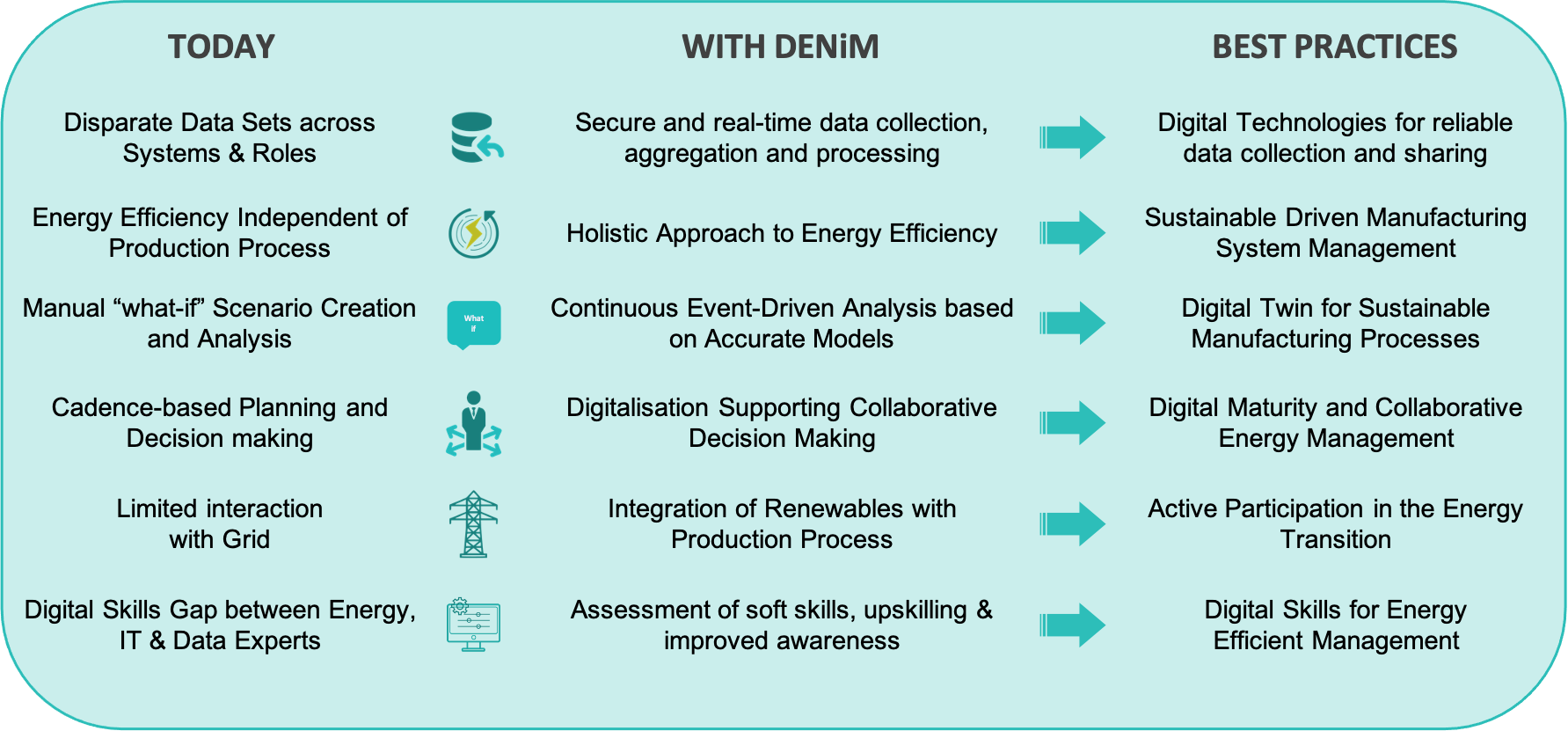

In order to achieve significant energy savings, the DENiM project will provide the ability to collect, analyse and communicate real-time and historical data, to optimise the performance and resource consumption at machine, process and factory, where decision support systems consider energy consumption globally.

The project is a 4-year partnership bringing together leading academics and industry with expertise in energy and ICT as well as representatives from various industrial sectors from across Europe.

DENiM will develop a digital intelligence platform that constitutes a suite of enabling tools and advanced digital services used to optimise existing workflows and product manufacturing, driven by energy efficiency targets and sustainability goals. The overarching goal is to define and promote the use of best practices across industry sectors within the EU to support the realisation of energy efficient manufacturing systems.