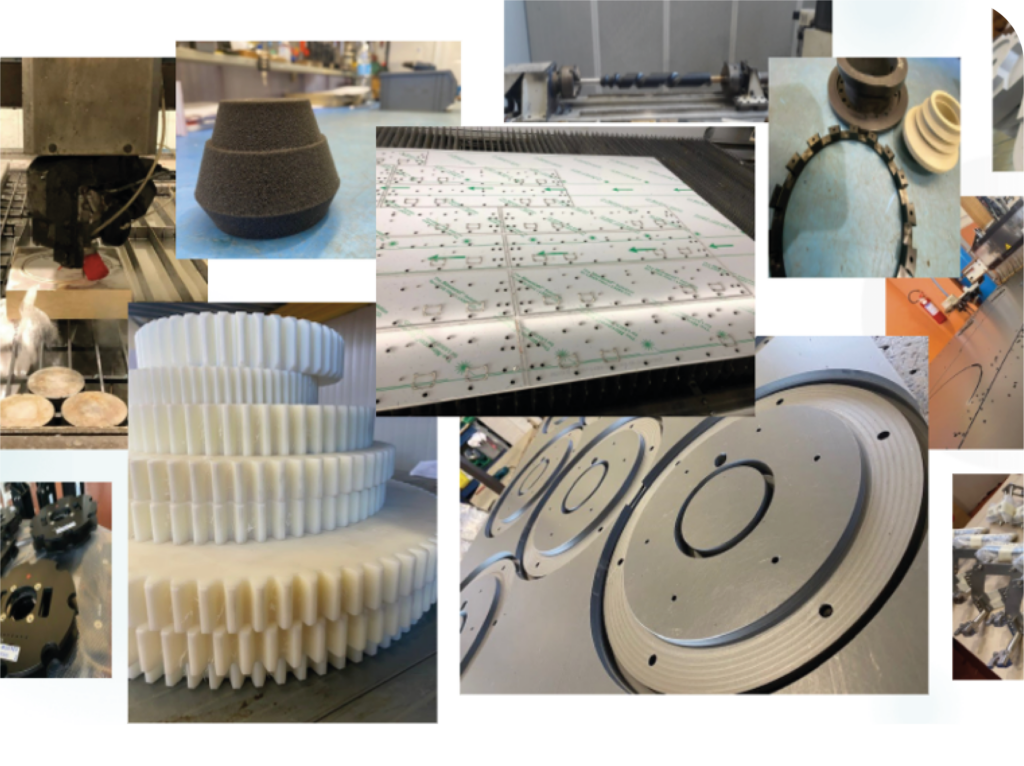

Plastics Processing

MET is a highly dynamic SME focusing on the production of mechanical components for the machinery industry. Acting on its highly variable production process DENiM will support the integration of loT based solutions for energy management, combining digital twin and energy modelling and optimisation technologies.

Objectives & Technologies

- Acquire visibility on the energy-related elements influencing production cost

- Introduce energy optimisation variable for optimal production set up and schedule

- Increase the monitoring of environmental impact of products

- Provide capabilities to visual asset energy use in “real-time”

Expected Targets

Digitalisation

100% increase of energy intensive machines monitored

Energy Efficiency

20% of energy will be saved via optimised planning and synchronisation of process steps

Cost Savings

LCC reduction of at least 10-20% of final product due to process optimisation